Advancement in the manufacturing of thin-walled cannulas demonstrated by Accumold at MD&M East

At MD&M East 2025, Accumold, a leading innovator in micro moulding, presented their latest advancements in this field, focusing on breakthroughs that enable the production of extremely small, complex plastic components with very tight tolerances essential for advanced medical applications.

Key highlights include:

- Advanced micro moulding capabilities that allow for the manufacture of highly precise, intricate micro-sized plastic parts used in medical devices, supporting evolving demands for miniaturization and complex geometries.

- Emphasis on sustainability practices integrated from the inside out in their micro moulding processes, reflecting a commitment to environmentally responsible manufacturing.

- Leveraging Artificial Intelligence (AI) and data-driven approaches to enhance precision, empower personnel, and strengthen customer partnerships, which improve quality and efficiency in medical device component production.

- Continued evolution of micro optics expertise, relevant to medical device optics components, showcasing Accumold’s expanding specialization beyond traditional micro moulding.

Accumold's 25+ years of experience in producing such solutions positions them as a leader influencing the future of MedTech through precision micro moulding innovations showcased at the event.

These innovations collectively demonstrate Accumold’s focus on addressing the stringent demands of medical device manufacturing by combining cutting-edge micro moulding technology with sustainability and smart manufacturing techniques.

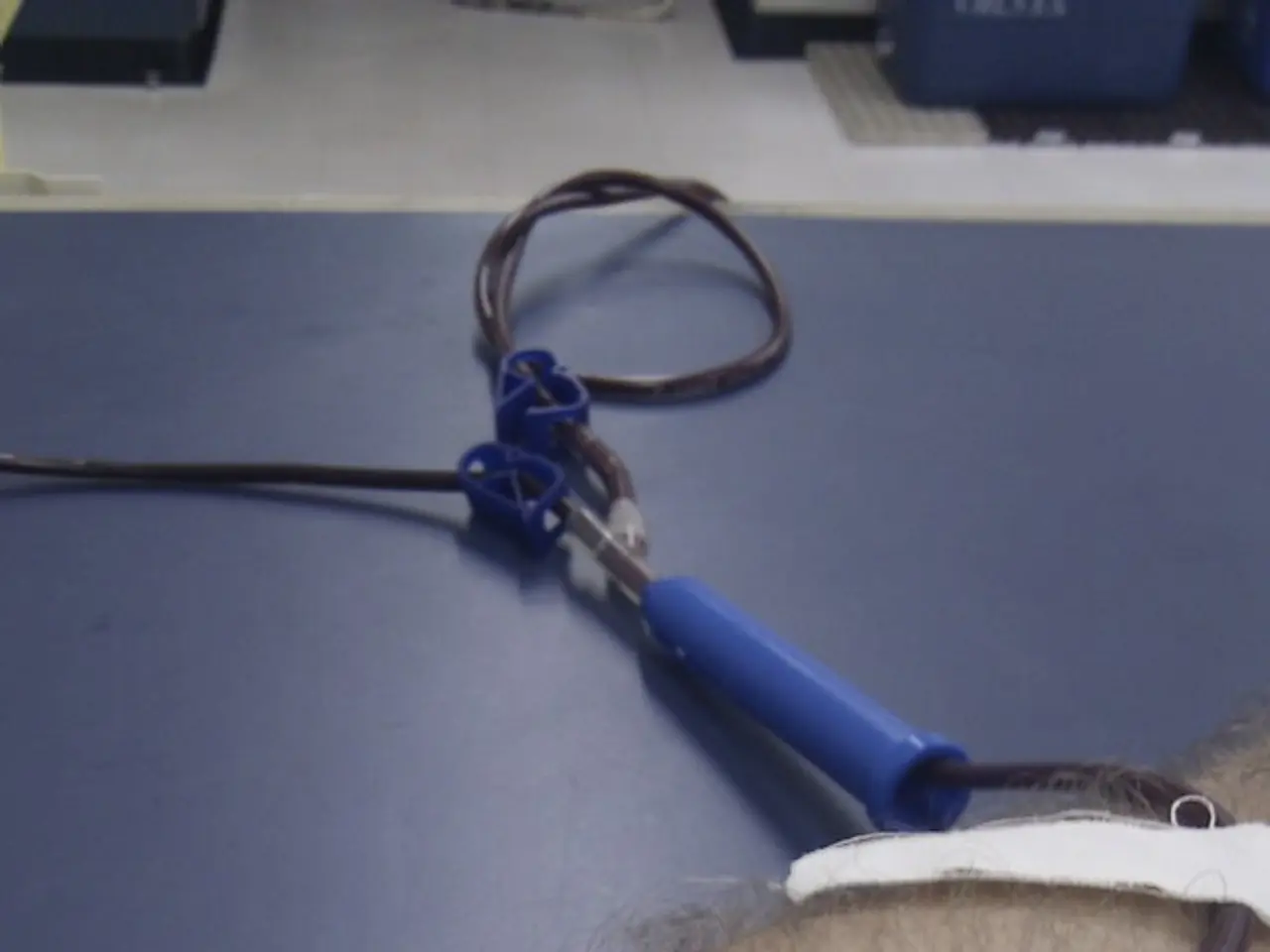

Brett Saddoris, Technical Sales Manager at Accumold, stated that this is a major step forward for minimally invasive devices. The new thin-walled cannula production technique, achievable through a single moulding process, allows for wall thicknesses as low as 0.1 mm and supports volumes of up to 40 million parts per year per cell, improving part quality and production efficiency.

These capabilities are particularly valuable in the development of minimally invasive and wearable medical devices. Visitors to Booth 551 can meet the technical team, view micro moulded samples, and discuss how micro moulding for medical devices can accelerate development and reduce time to market.

Accumold works with materials such as PEEK, LCP, Polycarbonate, Polypropylene, and Pebax for medical devices, including surgical tools, diagnostic kits, and drug delivery systems. Further information on navigating the complexities of micro moulding for medical devices can be found in "Medical Device Manufacturing Insights".

Accumold has over 40 years of experience in producing complex micro components with tolerances down to a few microns. The company's expertise extends to micro moulding for medical-grade materials. Additional insights on injection moulding of thin wall cannulas can be found in "Medical Plastics Insights".

Speed, consistency, and reliability are essential in healthcare manufacturing, as stated by Brett Saddoris. At MD&M East 2025, from May 20-22 in New York City, Accumold will showcase its latest innovations in micro moulding for medical devices.

- Accumold's advancements in micro moulding, showcased at MD&M East 2025, emphasize the production of intricate micro-sized plastic parts for medical devices, playing a crucial role in the health-and-wellness sector and medical device manufacturing.

- The company's technologies, which often utilize AI and data-driven approaches, are designed to ensure precision, efficiency, and sustainability in medical device component production, aiding in medical-conditions treatment with the use of minimally invasive devices.

- By focusing on the development of medical plastics and medical-grade materials, Accumold leverages its science and technology expertise to contribute to the evolution of healthcare manufacturing, particularly in the areas of medical devices and health care.